SACMA

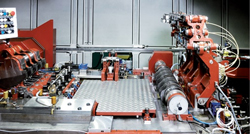

SACMA designs and builds machines in a manufacturing facility that the industry considers to be the most modern and best equipped in the world. At a time when many of our competitors are relocating their production to low-cost countries, we, in order to guarantee our undisputed quality, are expanding our manufacturing facilities in the “Italian Fastener Valley”. The mechanical component production is concentrated in two plants, SACMA and OBM, whilst the INGRAMATIC plant is dedicated to the production of thread rollers. Download SACMA Winning Technologies pdf.

Progressive Headers

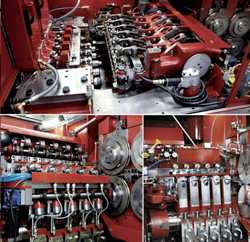

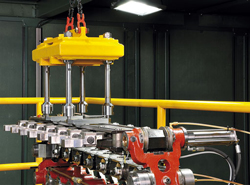

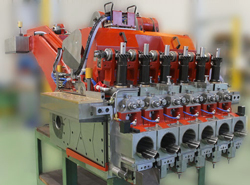

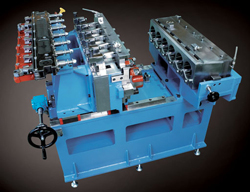

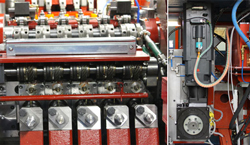

The high degree of precision in machining is a must for manufacturing machines that must operate with high productivity and efficiency. SACMA has chosen to manufacture, in house, all components and has installed the most modern production machines available today on the market, to promote the total quality of all SACMA Group products.

A systematic and rigorous inspection procedure of all manufactured parts before inventory stocking is the best guarantee of interchangeability and availability of spares. The correct choice of high tensile materials, the proper heat treatment specifications, the accuracy of surface finish operations of grinding and lapping make a SACMA machine the most reliable, the most productive and lowest cost machine in manufacturing.

The concept of performing tool change in the shortest possible time represents an undisputed necessity for modern industrial manufacturing of cold forged parts, made in smaller lots. In developing the quick tool change system, SACMA made no compromises of rigidity and power of the machines; a typical characteristic of its machines. The CR quick tool change system, standard for machines series 3, 4, 5 and 6, allows for easy removal of the die block, hydraulic clamped, and just as easy removal of the punch block bolster and the complete transfer unit. Download the Progressive Header Guide.

Combined Headers

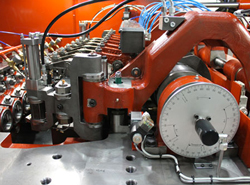

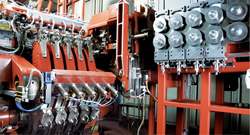

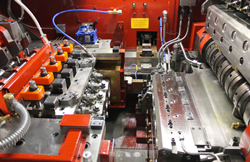

SACMA has chosen to manufacture, in house, all components and has installed the most modern production technology available today on the market, to promote the total quality of all its products. A systematic and rigorous inspection procedure of all manufactured parts before inventory stocking is the best guarantee of interchangeability and availability of spare parts. The correct choice of high tensile materials, the proper heat treatment specifications, the accuracy of surface finish operations of grinding and lapping, make a SACMA machine the most reliable, the most productive and lowest cost machine in manufacturing.

All SACMA machines are fitted standard with hydraulic clamping of die side adjustments of threaded sleeves, kick out levers and trim cam in the last station. The M automatic motorization system available on SACMA combined machines, is an important method for reduction of machine set up time and fine tuning adjustments. The preset data present in the data base of parts to be manufactured will determine the automatic adjustment of feed, position of stock stop and die kick out. Download the Combined Header Guide.

Warm Formers

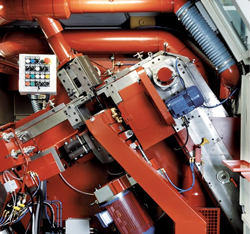

SACMA has chosen to manufacture, in house, all components and has installed the most modern production technology available today on the market, to promote the total quality of all its products. A systematic and rigorous inspection procedure of all manufactured parts before inventory stocking is the best guarantee of interchangeability and availability of spare parts. The correct choice of high tensile materials, the proper heat treatment specifications, the accuracy of surface finish operations of grinding and lapping, make a SACMA machine the most reliable, the most productive and lowest cost machine in manufacturing.

All SACMA machines are fitted standard with hydraulic clamping of die side adjustments of threaded sleeves, kick out levers and trim cam in the last station. The M automatic motorization system available on SACMA combined machines, is an important method for reduction of machine set up time and fine tuning adjustments. The preset data present in the data base of parts to be manufactured will determine the automatic adjustment of feed, position of stock stop and die kick out.