IMPAX | SK Technologies

IMPAX process monitors have held a strong position within the metal forming, stamping, and cutting industries for the past 20 years, with over 6000 successful installations. PTG is a market leader in the fastener industry in the United States, and also markets its monitoring expertise abroad. IMPAX process monitors use a patented algorithm to learn the correct force profile for a process, and then monitor that process. They make use of peak and area-under-curve analysis to provide robust consistency and machine protection.

PTG also offers products for efficiency and productivity monitoring, in the IMPAX Time Saver System. These monitors combine extensive data tracking with a user-friendly interface, to create a powerful machine efficiency and downtime tracking system. Time Saver monitors work as stand-alone units and are also networkable, forming a flexible and powerful production monitoring and downtime analysis system.

PTG also provides IMPAX/SK process monitors, via partnership with German monitoring company Schwer+Kopka GmbH. These monitors use a proprietary high-speed digital signal processor system, and provide advanced software features. These monitors are sold in the Americas under the IMPAX/SK Technologies label, and in Europe under the Schwer+Kopka label. The cooperative partnership of PTG and SK has been recognized for its innovative designs and technical excellence. From its inception, IMPAX/SK Technologies has brought to the market the unique ability to develop innovative turn-key solutions for a variety of metal forming, stamping, and cutting applications.

Benefits of Process Monitoring

Compact Process Monitoring Systems

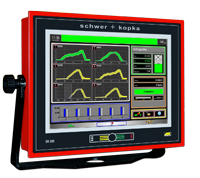

The new process monitoring units of our series SK 200 to SK 800 offer unprecedented ease of operation and feature a completely re-designed touch screen operating surface. All models are equipped with our proven Puzzlemaster expert routines and the advanced Mandonic auto enveloping technique as standard feature.

The models SK 300, SK 600 and SK 800 boost our unique Mandon®-Technology which is an intelligent messaging system providing the operator automatically with important information and suggestions based upon continuous observation of the current process, all aiming at improving overall productivity and quality.

Please note than some of the functions listed above are optional features.

Envelope Monitoring Systems

For cold forming machines. Top performance in technology, function, design and user friendliness. Technology with powerful signal conditining processors to provide the most advanced monitor available in the industry.