National Machinery

Precision Cold Forming Solutions

National Machinery is a global leader in advanced cold forming machinery, process technology, and customer support products & services. National Machinery offers a full spectrum of forming equipment to meet the needs of the global marketplace, while delivering the highest in quality and performance.

Products

The FORMAX 2000 cold former advances original FORMAX by raising performance and precision to an even higher level. The FORMAX 2000 design combines Zero-Clearance Heading Slide guiding, Straight across transfer, Sealed heading slide liners, Precision linear feed, system quick-change offline setup, and advanced computer controls into a forming system that delivers close-toleranced parts to net or near net shape.

The FORMAX 2000 cold former advances original FORMAX by raising performance and precision to an even higher level. The FORMAX 2000 design combines Zero-Clearance Heading Slide guiding, Straight across transfer, Sealed heading slide liners, Precision linear feed, system quick-change offline setup, and advanced computer controls into a forming system that delivers close-toleranced parts to net or near net shape.

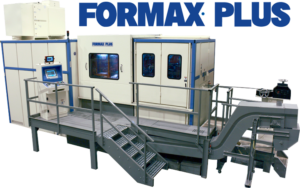

The FORMAX PLUS cold former meets the challenge of difficult-to-transfer and tight-tolerance jobs with the patented Pick-Move-Place transfer. The FORMAX PLUS cold forming machine has all the standard features of the FORMAX 2000 cold forming machines such as Zero Clearance Heading slide guiding, Sealed Heading slide liners, and Precision linear feed, but the FORMAX Plus also has increased forming tonnage, larger cutoff capacity, and expanded die space.

The FORMAX PLUS cold former meets the challenge of difficult-to-transfer and tight-tolerance jobs with the patented Pick-Move-Place transfer. The FORMAX PLUS cold forming machine has all the standard features of the FORMAX 2000 cold forming machines such as Zero Clearance Heading slide guiding, Sealed Heading slide liners, and Precision linear feed, but the FORMAX Plus also has increased forming tonnage, larger cutoff capacity, and expanded die space.

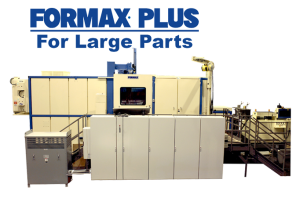

The FORMAX PLUS Cold Forming Machines for Large Parts are especially effective for forming complex shapes that require superior tolerance control. Proven FORMAX features, like Pick-Move-Place Transfer, and Zero-Clearance Heading Slide Guiding give FORMAX PLUS for Large Parts “net shape” forming capability. These large cold forming machines also bring an entirely new breakthrough in automated machine setup, changeover and monitoring. With push button control one operator can make a complete changeover in just 30 minutes.

The FORMAX PLUS Cold Forming Machines for Large Parts are especially effective for forming complex shapes that require superior tolerance control. Proven FORMAX features, like Pick-Move-Place Transfer, and Zero-Clearance Heading Slide Guiding give FORMAX PLUS for Large Parts “net shape” forming capability. These large cold forming machines also bring an entirely new breakthrough in automated machine setup, changeover and monitoring. With push button control one operator can make a complete changeover in just 30 minutes.

FORMAX Plus Short work models have increased tonnage and with Pick-Move-Place transfer handle those part shapes once thought too difficult to form.

With the expanded capacity of our Medium and Long work models, FORMAX PLUS for Large Parts takes on those high load, difficult to transfer and tough to form jobs you’ve always dreamed about making. With the fast changeover features like automated tool changer, and automatic adjustment of heading wedges, feed length, wire diameter, die kickout and transfer timing, FORMAX PLUS for Large Parts will be a welcome addition to your large part forming capability.

LeanFX combines the high performance standards of FORMAX® with the ease of operation and competitive pricing demanded by today’s global marketplace.

LeanFX combines the high performance standards of FORMAX® with the ease of operation and competitive pricing demanded by today’s global marketplace.

Many of the same innovative, production-proven features that were introduced on FORMAX, are standard on LeanFX, including Linear Feed, Zero-Clearance Heading Slide, Straight-Across Transfer and Sealed Heading Slide Liners. This global machine can produce high-quality fasteners and parts faster than any cold former on the market.

LeanFX is a FORMAX with efficient change-over features, designed to appeal to a wide range of standard and specialty fastener markets. Ideally suited for long production runs, LeanFX is equipped with simplified features such as Manual Adjustment of Feed and Die Kickout Length, a combined Electrical Control Cabinet and Operator Push- Button Station, and a Magnetic Finished Parts/Scrap Discharge Conveyor. A Free-Standing Sound Enclosure with new look and sound proof capability is also part of the standard machine configuration. The machine is available with the standard Straight-Across transfer or with Cold Former transfer in the 5-die version.

LeanFX is assembled at NM China, National Machinery’s wholly-owned facility in Suzhou, China. There, National Machinery personnel use the latest machine tools, inspection, assembly, and testing practices to ensure the highest level of quality. National Machinery experts in the areas of engineering, machining, assembly, and quality are stationed at NM China to ensure “National” quality of any product.

FORMAX machines can be custom designed for warm forming applications. The FORMAX Warm Forming machine has all the standard FORMAX features such as Zero Clearance Heading Slide, Precision Linear Feed, Sealed Heading Slide Liners and the Formapak Quick-Change System.

FORMAX machines can be custom designed for warm forming applications. The FORMAX Warm Forming machine has all the standard FORMAX features such as Zero Clearance Heading Slide, Precision Linear Feed, Sealed Heading Slide Liners and the Formapak Quick-Change System.

A FORMAX Warm Former can be either “prepared for warm forming” with basic specials, or customized based on the part application requirements and materials formed. This customization is important to have the right machine for the part application, not just a machine simply with a standard heater added. The specific Warm Former features that may be added include:

• High Frequency Converter

• External Circuit/Transformer

• Buss Bar

• Induction Coil

• Cooling System

• Converter and Induction coil

• Machine: Die block, Induction coil bracket & Die lube

• Heater for Die Lube

• Wire Temperature Sensor(pyrometer)

• Automated Blank Drop

• Blank or Feed Indicator

• Fire Suppression System

FORMAX XXV is a new 25 mm cutoff version of FORMAX. It combines the best features from small and large FORMAX like expanded die-space, high production speeds, pick-move-place transfer, zero clearance heading slide guiding, sealed heading slide liners, and precision linear feed, with all new technology including servo controlled adjustments and a robotic tool changer. This tool changer accesses an external setup fixture to make changes automatically without requiring a person to enter the die area of the machine. The XXV is available in standard and short stroke models with five, six, and seven dies.

FORMAX XXV is a new 25 mm cutoff version of FORMAX. It combines the best features from small and large FORMAX like expanded die-space, high production speeds, pick-move-place transfer, zero clearance heading slide guiding, sealed heading slide liners, and precision linear feed, with all new technology including servo controlled adjustments and a robotic tool changer. This tool changer accesses an external setup fixture to make changes automatically without requiring a person to enter the die area of the machine. The XXV is available in standard and short stroke models with five, six, and seven dies.

Inquire with your local National sales representative for more information on this exciting product.